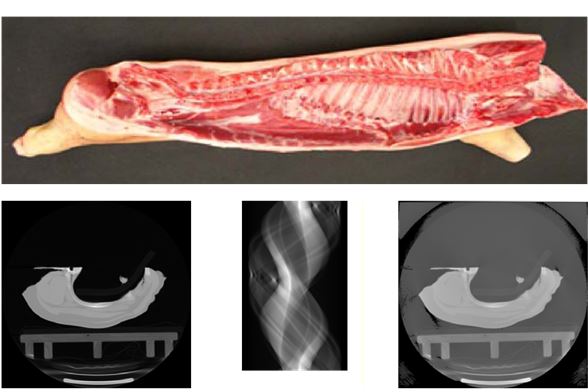

eScience-KU has been working on methods to simulate CT scanners to enable what-if testing of scanner designs before building the scanner, and testing the realtime performance one may obtain for industrial CT applications. One case is focused on developing and building a solution for efficient analysis and cutting of pork carcasses in slaughterhouses. The analysis is based on CT scanning and online reconstruction of the intersection images in the actual production line, so the results must be available within seconds in order to keep up with the production flow. As an example the meat intersection image in Figure 1 could result in detector readings as visualized in the sinogram, and we can then use e.g. filtered back projection to reconstruct an estimate of the actual intersection.

Figure 1 : Half a pork carcass (top), intersection of similar meat lying on a conveyor belt (left), the resulting scanning sinogram (center) and the reconstructed image (right) [New4].

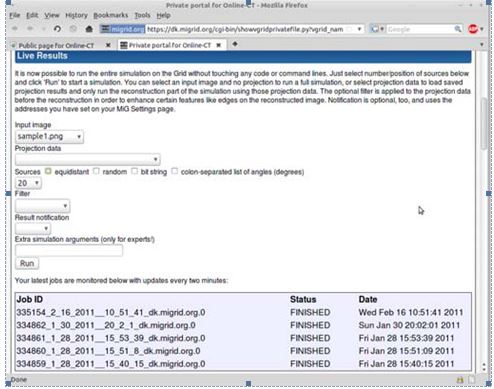

The case requires very high continuous usage of the CT scanner. Thus a number of design choices for the scanner had to be tested. The first technical task at KU was to provide inputs for the scanner setup decisions. Firstly, a grid enabled web portal providing interactive image reconstruction with variable source count and position was implemented (excerpt in Figure 2). Using the portal the project participants could easily investigate the image quality and thus the feasibility of various stationary source solutions.

Figure 2 : Web portal with live image reconstruction [New4].

The different simulated scans can then be passed to both quantitative and qualitative quality analysis. In KU experiments, the move from step and shoot fan beam to spiral cone beam CT removed a lot of mechanical challenges but instead introduced a huge amount of extra computation required in the already short period available in the production line. Thus the idea of using limited parallel optimization requirements had to be refined.

eScience-KU group has started to investigate spiral cone beam reconstruction implementations and the optimizations needed for the short time frame. It still seems to be possible to build a fitting solution using state of the art GPU hardware and a highly optimized implementation of the reconstruction algorithms but this target is still away from the required performance.

The group is currently working closely with the project engineers in building a working prototype of the scanner and showing that it is actually possible to reconstruct usable images albeit in a longer time frame. Once achieving this target, attention will be focused to image reconstruction performance and to integration with the further image analysis tools on the way from image to the cutting machine. The simulation environment, and the hundreds of CPUs that powers it, provides for a very convenient platform for testing CT scanner designs. In the future more reconstruction algorithms will be supported and a number of filters for the reconstructed images will be offered as well.